In industrial settings, the management of air quality is crucial for ensuring a safe and healthy work environment. One common challenge faced by many manufacturing facilities is the presence of oil mist, which can pose various risks to both human health and machinery. In response to this issue, the oil mist filter has emerged as a vital component in maintaining air quality and ensuring the efficient operation of machinery. Juwei will provide a comprehensive introduction to filter mist collector, covering their definition, working principles, applications, and benefits in industrial settings.

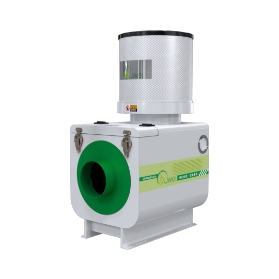

What is an Oil Mist Filter?

An oil mist filter, also known as a filter mist collector or oil mist eliminator, is a specialized filtration device designed to capture and remove airborne oil mist particles from industrial air streams. These particles are generated during various manufacturing processes such as metalworking, machining, and other applications where oil-based lubricants are utilized. The primary purpose of an oil mist filter is to improve air quality by preventing the release of these hazardous particles into the surrounding environment.

Oil Mist Filter Working Principles

Five-stage filtration. The first stage is composed of stainless steel braided mesh, which can capture larger particles that prevent iron filings and other impurities from penetrating the air purification system and causing interference or damage to the oil mist recovery and collection machine. 70% of the oil mist will enter the second stage of cyclone filtration and pass through the cyclone action generating static electricity, this electrostatic mechanism is particularly effective in handling submicron-sized particles, which can further absorb the oil mist on the stainless steel braided mesh.

In the third stage, a large screen with an enlarged surface area is used to optimize the oil recovery efficiency. In the fourth stage, a high-speed centrifugal impeller is used to generate a powerful suction cyclone, forcing the oil The mist adheres to the inner wall of the filter, and the intercepted oil mist is effectively collected by the internal oil barrier.

A barrel HEPA filter is used in the final stage. Most of the oil and larger particles have been removed through the previous four stages, and the HEPA filter only needs to capture remaining sub-micron fog and smoke particles and deliver highly purified air back to the work environment.

Oil Mist Filters Benefits in Industrial Settings

- Employee Health and Safety

- Equipment Longevity

- Comply with Regulations

Long-term inhalation of oil mist particles in the air can cause respiratory problems and pose health risks. Oil mist filters create a healthier working environment by effectively capturing and removing these particles, reducing the possibility of workers' respiratory diseases and improving employee health and safety.

Oil mist not only poses a threat to human health but can also damage equipment and machinery. The filter mist collector can prevent oil mist from depositing on the surface of machinery and equipment, causing corrosion and damage, extending the service life of the machine, reducing maintenance costs and ensuring optimal operating performance.

Many industries must adhere to strict environmental and occupational health regulations. Implementing oil mist filters helps industrial facilities comply with these regulations by mitigating the release of harmful substances into the atmosphere. This not only ensures a safer working environment but also avoids potential legal consequences associated with regulatory non-compliance.

| Item | Unit | Specification |

|---|---|---|

| HP | HP | 1HP 0.75KW |

| Air flow | m3/min | 20 |

| Air intake diameter | m/m | 150 |

| Voltage | V | 220/380 |

| Electric cuttent | A | 2.8/1.62 |

| Cycle | HZ | 50/60 |

| Speed | R.P.M | 2850/3500 |

| Noise | db | 68 |

| Weight | kg | 45 |

| Item | Size |

|---|---|

| A | 146 |

| B | 238 |

| C | 380 |

| D | 340 |

| E | 178 |

| F | 566.2 |

| G | 563.4 |

-

Stainless Net

Stainless Net -

PVC Tube Hose

PVC Tube Hose -

Wire

Wire -

PVC Flexible Duct Hose

PVC Flexible Duct Hose -

Hose Clamp

Hose Clamp -

Rubber Feet

Rubber Feet -

Flange

Flange -

Motor Starter

Motor Starter

Adjustable Hose

Adjustable Hose Ozone Machine

Ozone Machine Adjustable Stand

Adjustable Stand

In industrial settings, the management of air quality is crucial for ensuring a safe and healthy work environment. One common challenge faced by many manufacturing facilities is the presence of oil mist, which can pose various risks to both human health and machinery. In response to this issue, the oil mist filter has emerged as a vital component in maintaining air quality and ensuring the efficient operation of machinery. Juwei will provide a comprehensive introduction to filter mist collector, covering their definition, working principles, applications, and benefits in industrial settings.

What is an Oil Mist Filter?

An oil mist filter, also known as a filter mist collector or oil mist eliminator, is a specialized filtration device designed to capture and remove airborne oil mist particles from industrial air streams. These particles are generated during various manufacturing processes such as metalworking, machining, and other applications where oil-based lubricants are utilized. The primary purpose of an oil mist filter is to improve air quality by preventing the release of these hazardous particles into the surrounding environment.

Oil Mist Filter Working Principles

Five-stage filtration. The first stage is composed of stainless steel braided mesh, which can capture larger particles that prevent iron filings and other impurities from penetrating the air purification system and causing interference or damage to the oil mist recovery and collection machine. 70% of the oil mist will enter the second stage of cyclone filtration and pass through the cyclone action generating static electricity, this electrostatic mechanism is particularly effective in handling submicron-sized particles, which can further absorb the oil mist on the stainless steel braided mesh.

In the third stage, a large screen with an enlarged surface area is used to optimize the oil recovery efficiency. In the fourth stage, a high-speed centrifugal impeller is used to generate a powerful suction cyclone, forcing the oil The mist adheres to the inner wall of the filter, and the intercepted oil mist is effectively collected by the internal oil barrier.

A barrel HEPA filter is used in the final stage. Most of the oil and larger particles have been removed through the previous four stages, and the HEPA filter only needs to capture remaining sub-micron fog and smoke particles and deliver highly purified air back to the work environment.

Oil Mist Filters Benefits in Industrial Settings

- Employee Health and Safety

- Equipment Longevity

- Comply with Regulations

Long-term inhalation of oil mist particles in the air can cause respiratory problems and pose health risks. Oil mist filters create a healthier working environment by effectively capturing and removing these particles, reducing the possibility of workers' respiratory diseases and improving employee health and safety.

Oil mist not only poses a threat to human health but can also damage equipment and machinery. The filter mist collector can prevent oil mist from depositing on the surface of machinery and equipment, causing corrosion and damage, extending the service life of the machine, reducing maintenance costs and ensuring optimal operating performance.

Many industries must adhere to strict environmental and occupational health regulations. Implementing oil mist filters helps industrial facilities comply with these regulations by mitigating the release of harmful substances into the atmosphere. This not only ensures a safer working environment but also avoids potential legal consequences associated with regulatory non-compliance.